Veelo Technologies will introduce an innovative new out-of-autoclave (OoA) heated tool for composite processing at CAMX 2022. HyVarCVeeloHEAT is the new technology and is a hybrid Invar and composite mold with integrated VeeloHEAT® technology. It was created through a collaborative effort between Veelo and Ascent Aerospace.

Veelo Technologies will exhibit in booth #T20 at SAMPE 2022 and will feature new Out-of-Autoclave (OoA) heating and composite repair solutions, as well as lightweight lightning strike protection materials for aerospace and defense systems.

Build your future as a Production and Operations Manager with Veelo Technologies, a General Nano company. We develop composite protection materials and advanced heating solutions for composite processing and repair in the aerospace and defense industries.

Veelo Technologies has introduced a new small and lightweight form factor hot bonder used to control heat sources applied in composite processing and composite repair applications. The new hot bonder can be seen firsthand in Veelo's booth R58 at CAMX 2021, being held October 19-21, 2021, at the Kay B. Hutchison Convention Center in Dallas, TX.

General William M. Fraser III, former Commander of the U.S. Transportation Command (USTRANSCOM) has joined the company as a Special Advisor to Veelo's Board of Directors. General Fraser will partner with Veelo's Board, management team, and other key stakeholders to advance the company's strategic goals.

Veelo Technologies is excited to announce that the Naval Air Warfare Center Weapons Division (NAWCWD) (China Lake, CA) has exercised its option with Veelo (General Nano, LLC, dba Veelo Technologies) to accelerate the development of next-generation advanced solid rocket motor cases.

Mr. Larry Christy, Director of Research and Development at Veelo Technologies, will conduct an Education Session at CAMX 2021 entitled "Advanced Heating Solutions for Out-of-Autoclave, Out-of-Oven Composite Processing."

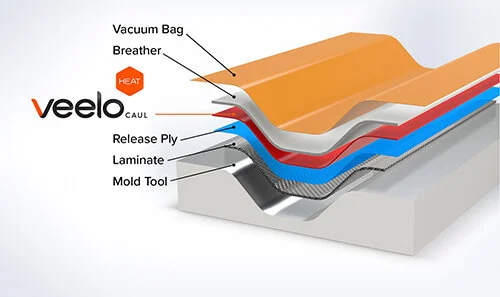

VeeloHEAT Blanket from Veelo Technologies provides uniform and reliable heating for composite curing applications and helps manufacturers keep composites out of the curing oven. The innovative design of the VeeloHEAT Blanket results in a bendable, drapable blanket that will more easily conform to complex geometries commonly found in composite manufacturing.

Veelo Technologies helps composite rotor blade manufacturers and repair facilities keep blades out of the oven (OoO). Veelo’s heating blankets can be tailored for use in debulking and bonding applications and can be used in-situ, eliminating the need to transport long and bulky rotor blades to an oven.

Industry 4.0 and IIoT are of course big topics that are still being fully explored and defined in industry. From our standpoint, its implementation allowed us, as a startup company, to be agile and get equipment controls up and running quickly.

Please join our President and CEO, Mr. Joe Sprengard, Jr., as he joins a panel discussion at the event on January 11th at 1:15 PM.

The Naval Air Warfare Center Weapons Division (NAWCWD) (China Lake, CA) has contracted General Nano, LLC (dba: Veelo Technologies) to enhance the performance of traditional graphite epoxy composite tactical missile solid rocket motor cases.

Veelo Technologies is leveraging its innovative composite processing technology to help manufacturers stay out of the autoclave and oven and by improving their debulking processes. The company’s solutions allow effective and reliable in-situ hot debulk, eliminating the need to transport parts to an autoclave or oven.

Utilizing proprietary heating technologies, Veelo Technologies’ is helping reduce costs and increase production of composite parts that will be used on the fifth-generation combat aircraft. Veelo will provide VeeloHEAT Cauls and VeeloHEAT composite repair blankets based on the company’s novel heating technology.

Mr. Larry Christy, Director of Research and Development at Veelo Technologies did a presentation CAMX 2020 entitled Advanced Heating Solutions for Accelerated Cure of Adhesives and Sealants. According to Mr. Christy, “I will touch on a number of the challenges faced by industry when manufacturing and processing composites, and present innovative solutions we manufacturer here at Veelo.

Composite materials have been adopted in many industries for a wide range of applications due to the strong mechanical and highly conductive properties that can replace metallic structures. One prime example is in the modern aerospace industry. Combined with the advantages of being light and flexible, composite materials have the capabilities to shield the aircraft from electromagnetic interference and to protect the aircraft from lightning strikes.

“AS9100D is essential for a company like Veelo Technologies that has made the transition from an R&D startup effort into a true and trusted supplier of products within the aerospace and defense industries. The certification lets our customers and potential customers know that we are serious about the quality and safety of our products. Adopting these requirements helps us improve and maintain quality, costs, and delivery performance.”

The new site is reflective of Veelo’s growth, highlighting the company’s complete portfolio of solutions including electrically conductive materials, advanced heating solutions for composites, and next generation de-icing systems.

AS9100D is an international standard that governs quality systems for companies providing goods and/or services to the aerospace, space, and defense industries. The standard provides supplier requirements and best practices for areas of the business including Context of the organization, Leadership, Planning, Support, Operation, Performance Evaluation and Improvement. Adopting these requirements throughout the entire supply chain results in improved quality, cost, and delivery performance.

How could something so cool, techy, and ‘cutting edge’ also be so frustrating, painfully slow to development, expensive, yet filled with optimism and possibilities?

Welcome to my experience with nanotechnology, and the story of how General Nano pivoted to become Veelo Technologies.

Veelo Technologies has achieved a new milestone in the high-growth aerospace and defense composites protection market. VeeloVEIL, a metallized nonwoven advanced material, is now available in 3 mOHM/sq, 55 grams per square meter with >95% electrical uniformity in a 36” wide continuous product form. VeeloVEIL’s electrical conductivity and basis weight properties are unmatched by incumbent solutions, making it the highest performing composite protection material in the market.

“I will touch on a number of the challenges faced by industry when manufacturing and processing composites, and present innovative solutions we manufacturer here at Veelo. For example, our customers are dramatically reducing adhesive cure time with the use of VeeloHEAT Blanket. The cure time of adhesives in the aerospace market today are a limiting factor in throughput, as the cycle time for room temperature curing adhesives and sealants can takes upwards of 24 hours or more. I will discuss how by using VeeloHEAT Blankets, these adhesives can be cured in under 2 hours, even as low as an hour when cured at an elevated temperature of 180°F or higher depending on the adhesive chemistry.”

VeeloVEIL is an extremely light and conductive metallized nonwoven used by the aerospace industry to protect composite aerostructures from environmental and man-made hazards, and improve survivability.

Veelo Technologies was awarded $2.9M to accelerate the manufacturing readiness level of VeeloVEIL, a patent-pending advanced material for electrically conductive composite systems on commercial aerospace and defense platforms. VeeloVEIL is an ultra-lightweight, highly conductive material that meets the most stringent lightning strike protection, EMI shielding, and other electromagnetic effect requirements. For more information, please contact Tom Sorenson, Director of Business Development at tom.sorenson@veelotech.com; 385-449-8444, or sales@veelotech.com.

Veelo Technologies, an advanced materials company that partners with the world’s leading companies to improve the performance of high-value systems including commercial and military aerospace assets, has successfully completed its expansion into a new manufacturing facility. The new facility, located near GE Aviation’s global headquarters in Cincinnati OH, supports Veelo’s growth in electrically conductive materials and heating solutions for the fast growing aerospace composites industry.

Effective November 1, 2018, Veelo Technologies® expanded its operations and is moving to a new manufacturing facility to support the company’s current and future growth. The company’s product portfolio is experiencing new customer adoption for lightning strike protection and EMI shielding, electro-thermal deicing, and heating solutions for composite repair and out-of-autoclave/out-of-oven composite manufacturing.

Advanced Metallized Nonwoven for Lightning Strike Protection and Electromagnetic Environmental Effects

Developed with aerospace and defense customers to meet the most stringent lightning strike protection and electromagnetic environment effects requirements in composite air vehicles.

2015 Supplier of the Year — Technology

The Boeing Company, the world’s largest aerospace company, announced this recognition April 13, 2016 at Boeing’s Global Supplier Conference at the Washington State Convention Center.

This marks the second win for General Nano | Veelo™ since 2013.

General Nano | Veelo™ is on the rise and industry experts are taking notice.

Veelo BLAC™, a super-black material that absorbs more than 99.6 percent of light, will be traveling to space as part of NASA’s Earth Science CubeSat Program on a 2018 mission to the International Space Station.

Tweets

by @VeeloGN

-

Veelo Technologies launches a new, lightweight Single-Zone Hot Bonder at CAMX! Check it out ...Booth R58 https://t.co/9nZBlEOkIY

-

We are honored to have (retired) Four Star General William M. Fraser III, USAF serve as a special advisor to Veelo… https://t.co/BhODF5CO0a

-

Excited to share Naval Air Warfare Center Weapons Division (NAWCWD) has expanded relationship with Veelo Technologi… https://t.co/Yp9bdbAUBE

-

Learn more about how Veelo Technologies delivers the heat. Where you need it. When you need it.… https://t.co/6cNzrH1Zas

-

Innovation. Veelo leaders discuss scaling our chemistry to deliver new capabilities. https://t.co/pNaXKmZQVp… https://t.co/cFGDwZjj8D

-

Veelo Technologies teams with Lockheed Martin and the Navy to reduce F-35 program costs @JECComposites https://t.co/MxKtMESp0b

-

Excited to partner with @theF35JPO, @LockheedMartin, @ATI_ORG to deliver new cost reduction and throughput capabili… https://t.co/N0x6kx26Br

-

We are proud to announce our partnership with Lockheed Martin and the Navy on the F-35 program. Our advanced heatin… https://t.co/YUd7Xm6NJB

-

In case you missed it, CW covered our recent accomplishments on VeeloVEIL https://t.co/h9K3HzW4Mk

-

Solving challenges in the growing aerospace and defense composites industry created an opportunity for Veelo Techno… https://t.co/EymDcEXMH0

-

Thank you @TechOhioGov for your support. Excited for next chapter of growth. https://t.co/MomcLbT8fV

-

RT @HCBCtr: Thank you to Joe Sprengard of @VeeloGN for speaking at today’s @theHCDC Manufacturing Discussion in Village of… https://t.co/evB0x8Kj3R

-

Thankful to have #Raytheon delivering one our most capable weapon systems. #Tomahawk #NAVAIR #NAVSEA https://t.co/cBK8z8MEsL

-

TY @CompositeWorld for hosting @VeeloGN on CW Podcast. Always fun talking about our dynamic industry & what lies ah… https://t.co/jHMCGSjRma