Description

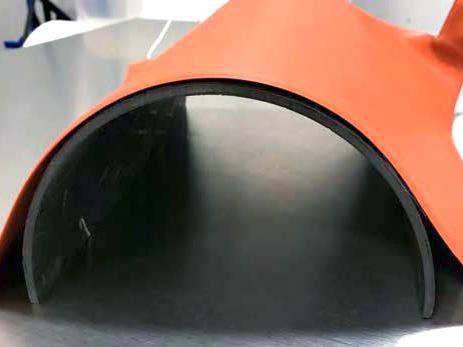

VeeloHEAT Blanket is a non-metallic heating solution for advanced composite applications that demand excellent thermal uniformity, drapability and durability.

24 month old technology that has been selected for major DoD production programs to bond multi-million dollar composite aerostructures. Helped customer reduce adhesive cure cycle-time from 24 to 2 hrs.

Features

Lightweight, uniform heating solution for advanced composites

Enables durable, lightweight, damage-tolerant and low-power ice protection systems

Tailored heating, density, areal weight, and thickness

Composite repair blankets

Heated debulks

Clean room elevated tool heating

Autoclave cycle time reduction

Benefits

Electrically efficient, fast heating and cooling

Highly uniform across large surface areas

Conformable to complex curvature parts, such as engine inlets

Fatigue resistant

Custom shapes

Can be trimmed to fit

Scalable for large tools

Applications

Out of autoclave and out of oven processing

Composite repair

Bonding aerostructures

Accelerating adhesive cure

Elevated tool heating — replacing heat gun

Improving debulk & compaction

Heated cauls

Heated Composite and Metallic Tools

technical specificationsVeeloHEAT Blanket available in the following specific options: |

|

| Material Options | Silicone, Reinforced Silicone, Viton |

|---|---|

| Temperature Ranges | 100°F–400°F |

| Maximum Size (inches) | • 24x72 Single Zone • 60x96 Multizone • Customizable by geometry |

| Thickness | • 1.5 mm – For Maximum Drapability • 3 mm – With Fiberglass Reinforcement for Maximum Durability • Viton – For Clean Room Requirements |

| Power Density (W/in2) | 2–30 |

| Input Power | 24–480 VDC |